Slate is known for its durability and classic appeal, making it an ideal choice for both practical and aesthetic purposes. One of the key advantages of slate is its natural resistance to components. It is able to withstand severe weather, including heavy rain, snow and intense sunlight. This material presents longevity and minimal up-keeping. It is both a dependable and cost-effective option for those who are looking for lasting quality.

UK slate had the pleasure and privilege of supplying bespoke slate for Gail’s Artisan Bakery refurbishment in London. This project involved no less than 1,878 bespoke Ravendale Riven tiles being cut into triangles by our specialist slate experts, which equipped Gail’s Artisan Bakery with the finishing touches that they required.

Using slate in architecture and design has unlimited design opportunities. It is very adaptable and can be used in many different shapes and forms. It is easy to incorporate this material into any arrangement. At UK Slate, we provide everything slate all in one place, including roofing, flooring, landscaping, and even bespoke.

When it comes to selecting materials for large commercial projects, businesses need to find the ideal balance between aesthetic appeal and functionality. Among a considerable number of alternatives, slate stands out as versatile, durable, and affordable, which brings multiple advantages. Whether you’re undertaking a new project or remodelling, slate offers beauty, longevity, and practicality, which makes it the ideal choice for any business.

Aesthetically Pleasing

Slate is aesthetically pleasing due to its natural variations in colour and texture. It’s a naturally occurring stone, unlike any other manufactured materials. The riven surface of the slate makes it distinctive, and the slightly irregular texture adds depth and character.

Customers are drawn in by aesthetic appeal; when a business presents a visually pleasing design, it fosters a sense of desirability and encourages customers to engage with the business. Slate is known to be elegant and clean, which can be utilised for a minimalistic design and is perceived as sophisticated and friendly.

The aesthetic is a major factor for higher engagement, as customers are more likely to interact with businesses and brands with visually inviting aesthetics.

Stain & Scratch Proof

Slate is stain-resistant, which makes it low maintenance. This means spills and dirt can be easily wiped away without damaging the surfaces, leaving permanent marks, scratching, etc. This makes it ideal to use in busy areas like businesses where spills and scratches are common, such as in cafés or retail stores. Slate preserves its immaculate appearance for a long time compared to other materials. Whether used in flooring, countertops or feature walls, slate will look good for years to come without the need for constant repairs and replacements.

Low maintenance

Maintaining a commercial space can be challenging, time-consuming and expensive. However, slate makes it way more manageable. Due to its impermeable surface, slate resists stains, dirt and dust way better than any other material. This reduces the need for frequent cleaning, which saves businesses time and money whilst keeping spaces consistently looking flawless and professional.

In any commercial space, slate’s easy-to-clean nature makes it a low-maintenance option for busy businesses. All you need to do is wipe the surface down every now and then, and you should be good to go.

Waterproof Properties

The waterproof property of slate makes it an excellent material choice for commercial spaces as it reduces the risk of any water deterioration, which means less cost of repairs. Slate is a reliable and resilient choice for commercial space over time.

Longevity and Durability

Durability is essential for businesses, especially in high-traffic areas. The overall quality of slate contributes to its longevity and durability, making it the ultimate heavy-duty material. Therefore, it is perfect for any busy business environment.

Versatility

Another one of slate’s known qualities is its versatility; this material can be used in a wide range of applications both indoors and outdoors, perfect for businesses that want to merge this material into various design features.

Whether you need to use slate for roofing, floors and walls, countertops and surfaces or other areas, slate delivers a clean, sleek surface that can withstand heavy use whilst being easy to maintain, making it a flawless option for businesses looking for aesthetic appeal and durability.

Cost Effective

Its long-term cost-effectiveness creates an excellent choice for businesses. Slate reduces the need for recurring repairs, saving businesses money in the long run. Additionally, its ease of cleaning and upkeeping means businesses can keep their spaces looking fresh and professional without splurging on maintenance costs.

In conclusion, when it comes to businesses, slate offers a range of benefits, from its distinguished aesthetics and versatility to its durability and cost-effectiveness. Slate provides the perfect balance between innovation and function.

If you’re planning on renovating or starting your business, contact us at 01539559289 or fill out our inquiry form online with any other questions. We will provide additional information on how our bespoke slate services can benefit you and your business.

The ‘Slate District’ is a term for the region of the Lake District in England, North-West UK, mainly within Cumbria’s Barrowdale Valley where slate has been quarried over the centuries. Some of the best-known slate mines in the district are Honister Slate Mine, Elterwater Quarry and Kirkby Quarry.

The Lake District was made a UNESCO World Heritage Site in 2017 due to its stunning scenery and cultural heritage. Over the years, this recognition has only served to enhance the significance of its historic slate industry. The region’s natural beauty and the tradition of slate mining contribute to its uniqueness, making it a site of cultural and geological importance.

Slate quarrying has been at the heart of the architecture as well as the economy of the Lake District. Slate quarrying began during the Roman times but gained momentum with the Industrial Revolution through the Cumbrian slate’s high demand since it was durable and aesthetic to the eye. Honister and Kirkstone villages are among the most well-known quarries, which to this day supply better quality slate that is also used both for repair works during historic periods and for standard building construction.

Slate was used for roofing, flooring and writing slates. It was a widely used material that was utilised in the 17th and 18th centuries since it is not a flammable and tough material. Slate was also utilised in schools in the 19th and 18th centuries to teach children how to read and write.

Cumbrian slate remains a favourite among roofers, floorers and landscapers today, not only in the UK but internationally. It is a sedimentary rock that is produced in Cumbria, England famous for its looks, durability and functional appeal. Its strength and timeless elegance are favoured by architects and engineers. Some of its contemporary uses are:

Cumbrian slate has been quarried for centuries with the colour usually dependent on the area it’s mined out of. The most common types of Cumbrian slates are the Westmorland Green slate and the Burlington Blue slate.

The future of the slate industry is promising with growing demand for sustainable materials, better quarrying techniques and attempts to preserve historic buildings. Green mining practices ensure that there is a balance between business and environmental responsibility. Local communities are still dedicated to making the historical value of slate mining more significant while keeping the industry alive for generations to come.

Slate can be found in Lake District, Cumbria in quarries and mines. Visitors to the Slate District can learn about the history of slate mining by:

The extraction of slate from the Lake District has altered the scenery to an extent. Through the production of large open quarries, mining plants and rock faces, it has had a noticeable impact on the landscape.

If you are interested in incorporating Cumbrian Slate in your next construction projects, or want to know more about its history and uses, visit our website for more information on a range of product offerings such as slate roof tiles, floor slates and landscaping and architectural slate options. And for any additional questions, get in touch with us on 01539 559 289.

At UK Slate, we’re convinced that strong relationships are the basis of a thriving business, both with our customers and our suppliers. Earlier this year in February 2025, our managing director, Kevin Robley, and sales manager, Neil Purcell, visited our established supplier, Black Slate, in Brazil.

The aim of our visit was to gain direct knowledge of the production procedure behind our premium Ravendale and Elterdale slates. We’ve worked with Black Slate for numerous years, but nothing is better than meeting in person, seeing the thorough craftsmanship behind each slate and strengthening the partnership that guarantees we bring the best products to our clients.

Luciano Barcelos, CEO of Black Slate, gave us a warm welcome, devoting a full week of his own time to personally guide us through every aspect of their procedure. From the quarry to the finishing process, we witnessed the level of skill, care, and dedication that goes into constructing the slate we proudly display at UK Slate.

One of the key outcomes from our visit was the realisation that our company values are extremely aligned with Black Slate. Their team operates with the same commitment to quality, reliability and ethical business practices as our team at UK Slate.

Meeting the hardworking employees behind the scenes, from quarry workers to production experts, offered us continued gratitude for the effort and passion that goes into every piece of slate. These sorts of connections, built on trust and mutual respect, are what positions UK Slate apart from other businesses.

Who said all business trips have to be strictly just business? It wouldn’t be complete without a little break! After exploring the quarry and production facilities, we had the opportunity to experience some of the sights and culture of Brazil. It was the perfect way to reminisce on an inspiring trip and the unique connections that make our partnership thrive.

Our visit reinforced our trust in the distinctive quality of Ravendale and Elterdale slates, and we’re excited to continue operating with Black Slate for years to come.

If you’re interested in learning more, make sure to explore the variety of premium Brazilian slates that we have to offer: Elterdale Slates & Ravendale Slate.

For further inquiries, make sure to get in touch with our team, we’d love to help you find the ideal slate for your current or upcoming projects!

When working on a building, one of the most important considerations to make is the preservation of its original aesthetic so that the historical essence of the building is not lost. The visual components of a building are sometimes what make it so different when compared to others, a quality that also makes it unique and special – and if the building is listed, then this is even more necessary since a major change can make it lose its status.

When carrying out new work, such as building extensions or modifications, it’s crucial to keep in mind that the old and the new should look the same as if the same architects and designers did them.

Take flooring, for example. When replacing the original flooring in a traditional building, it is of paramount importance for the new floor to reflect the colour, texture and finish of the old stone. Many traditional buildings in the UK may have used flooring from local sources when originally constructed, which may no longer be available or accessible today. Many native slate quarries are still operational today, e.g. Welsh or Cumbrian sources; however, you may find your project’s budget will become strained by the cost of these premium materials.

But worry not! There are many cost-effective alternatives to these materials that are visually sympathetic and available in a range of finishes, making it even easier to match the original.

Our Ravendale® and Elterdale® flooring ranges are available in a tumbled finish, which would be excellently suited to flooring projects that aim to be authentic to the worn, aged appearance of old flagstones. The gently chipped and rounded edges resemble a floor which has tolerated decades of wear and tear. The Ravendale® and Elterdale® colours provide cost-effective alternatives to Welsh Dark Blue Grey and Cumbrian Green slates, respectively.

Slate’s natural beauty is not solely in its appearance. The stone exhibits a unique range of hues—from the deep, evocative Welsh Dark Blue Grey to the rich, earthy tones of Cumbrian Green—which are the result of its geological origins. The naturally occurring grain lines and textured surface, often enhanced by tumbled finishes, perfectly mirror the centuries of weathering seen in traditional structures.

Utilise digital colour-matching tools to ensure that new materials accurately replicate the hues of the original slate and factor in potential lead times from quarries or suppliers. Consulting with architects experienced in heritage restoration will further ensure that every detail—from flooring to roofing—resonates with the building’s historic essence.

In order to preserve the original aesthetic, architects and builders should first understand what the heart of the design is so as to be able to adapt to each building’s needs and maintain its integrity. Once established, a project that intends to preserve the aesthetic instead of a complete renovation should change as little as possible. Major structural modifications should be avoided, as they would completely alter the design.

This means that any changes, internal or external, should be minimal and necessary. If your flooring project does not entail the removal of the entire flooring surface in a given space but instead patchwork where flooring may be damaged, then it would be advised that like-for-like materials are sourced prior to the removal of any original flooring. This would also allow for planning around long availability lead times.

It is also worth recognising that slate has been a cornerstone of UK architecture since medieval times. From the majestic facades of historic castles to the enduring roofs of venerable churches, slate not only preserves historical accuracy by mirroring original quarry sources but also embodies traditional craftsmanship through age-old splitting techniques.

Beyond flooring, slate’s versatility supports a range of restoration applications. Its inherent durability and weatherproof qualities make it ideal not only for roofing but also for external cladding, landscaping elements such as garden paths or patios, and even interior detailing like fireplaces and worktops. By utilising slate in these diverse applications, one can ensure that every facet of a building remains true to its historical narrative while benefiting from modern durability and sustainability.

It is clear that the only way to guarantee the preservation of a building’s aesthetic while conducting new work is through tailored solutions. It’s important to remember that there is generally not a one-size-fits-all remedy and that detailed research and design are the keys to success.

When considering cost, it is essential to note that while natural slate is a premium product, its longevity—often exceeding a 100-year lifespan—renders it a cost-effective choice in the long run. Moreover, slate boasts one of the lowest carbon footprints among roofing materials due to its minimal processing and 100% recyclability. For projects with tighter budgets, alternatives such as our Ravendale® and Elterdale® ranges offer a visually compatible and sustainable solution without compromising on historical integrity. If you require any advice or guidance with regard to a restoration project, please do not hesitate to contact our staff; their expertise will guide you through the process of your project. You can also find us on Facebook or LinkedIn, so head over and check out our projects in more detail.

We are delighted to announce the arrival of the Burlington Blue Grey Best Slate, now available at UK Slate. This remarkable slate, sourced from the heart of England’s Lake District, is celebrated as one of the finest slates in the world. Renowned for its striking blue-grey hue and superior quality, it’s the perfect choice for premium projects where only the best will do.

The Burlington Blue Grey Best Slate is available from stock in two versatile options:

Sold by the tonne, with a variety of crate sizes in stock, this slate is ideal for projects requiring flexibility and precision.

The unique qualities of Burlington Blue Grey Slate have made it the choice of architects, designers, and builders for centuries. Its durability and timeless aesthetic elevate both modern and traditional projects. Each piece undergoes rigorous testing to meet BSEN12326-1:2004 standards, achieving A1, T1, and S1 certification, ensuring its strength, water resistance, and thermal performance.

Burlington Blue Grey Best Slate is not just a roofing material; it’s a statement of quality and heritage. Its versatility makes it suitable for:

As a registered stockist of Burlington products, UK Slate is proud to offer not just the Blue Grey Best Slate, but also a full range of Burlington slates, including the renowned Westmorland Green slate. Whether your project requires roofing, architectural elements, or aggregate materials, we are your trusted source for premium Burlington slate.

When choosing materials for your project, nothing compares to the blend of heritage, beauty, and performance that Burlington Blue Grey Slate offers. Its origins in the historic Lake District lend it a character and prestige that other materials simply cannot replicate.

If you’re ready to elevate your next project with the finest slate in the world, contact us today. Let’s discuss how Burlington Blue Grey Best Slate can bring your vision to life.

We are happy to announce the arrival of our Ravendale® 9-11mm Blue Grey Slate, now in stock here in the UK. This premium slate combines strength, durability, and timeless aesthetics, making it an excellent choice for roofing projects of any size.

Created in collaboration with our trusted quarry partners in Brazil, the Ravendale® Blue Grey Slate delivers exceptional quality and consistency. Sourced from a select section of the Black Slate quarry in the Paraopeba Valley near Papagaios, Brazil, this slate is celebrated for its outstanding stone. By producing the Ravendale® exclusively in a 9-11mm thickness, we ensure that each piece meets the highest standards of durability and performance.

We have a very close relationship with our Quarry partners in Brazil, this ensures we maintain unparalleled control over the quality and integrity of the product. In fact, Ravendale® slate is sourced only from the finest areas of the quarry, ensuring a denser, stronger product that will stand the test of time.

The Ravendale® Blue Grey Slate is available in a range of sizes to meet the diverse needs of our customers:

Whether you’re working on a modern project or a traditional design, these size options ensure flexibility and compatibility for any roofing requirement.

The blue-grey colour of the Ravendale® slate is a striking and cost-effective alternative to higher-specification slates such as Burlington or Welsh slate. While offering a similar aesthetic and performance, the Ravendale® delivers exceptional value, making it a popular choice among professionals and homeowners alike.

The Brazilian slate industry has emerged as one of the leading global suppliers of natural roofing slate, and the Ravendale® Blue Grey is no exception. Backed by well-regarded international quarrying and production facilities, this slate is manufactured with precision and an unwavering commitment to quality.

Every Ravendale® slate undergoes rigorous testing to ensure it meets British and European standards. It is fully certified to BS EN12326-1:2004, attaining A1, T1, and S1 ratings for strength, thermal resistance, and water absorption. These certifications provide confidence that the slate will deliver long-term reliability, even in challenging UK weather conditions.

At UK Slate, we take pride in offering products that reflect our values of transparency, reliability, and quality. Our direct partnerships with quarry owners provide full visibility into the supply chain, ensuring that you can trust the origin and integrity of every piece of Ravendale® slate.

Our experienced team, based in the heart of the Lake District, is here to help you make the right choice for your roofing needs. With a team that carries many decades of combined expertise, we’re always happy to provide advice, answer questions, and guide you through the selection process.

To discuss your project and request a quote, please get in touch with us. We’ll be happy to provide a tailored solution to meet your needs. Discover the benefits of the Ravendale® Blue Grey Slate and elevate your next roofing project with this exceptional product.

Natural slate is a material that has been embraced as a way to improve any premises, whether it be with landscaping, roofing or interior improvements. Few materials will surpass the inherent beauty of natural slate tiles, and it’s not even limited to domestic uses only.

Using slate, whether in your home or commercial property, can give you a lot of benefits. After all, this stone can be used for the outside, such as for the exterior walls of your home or the roof, or indoors to create a beautiful design you can be proud of at all times.

Slate is a highly versatile stone capable of being used in an extensive range of applications, and it’s widely regarded as a natural stone that offers sophistication and style to any design. One of slate’s most remarkable features is its ability to be adapted and worked to your specific needs, meaning you can add a unique, authentic look to your home or business if you opt to use this natural stone.

At UK slate, we embrace the beauty that natural slate provides while working to ensure that our customers are able to implement their slating in the exact way they wish. There are plenty of options when choosing a natural slate. This versatile material can be manipulated into many sizes and be supplied in a variety of colours.

This natural stone can provide beautiful designs that add style and beauty to any room – however, this feature begs the question, ‘what makes slate so aesthetically pleasing?’ Its natural appeal, as well as the honing process it goes through, greatly contributes to this characteristic.

When the tiles are machined to a honed flat finish, the process involved cuts through the minute undulating layers within the slate and can create a billowing cloud effect. This is because the honing procedure enhances the variations of shade within the stone, sometimes leaving plain tiles, other times beautiful swirling patterns that are unique to each tile. This flexibility is perfect for creating a wide array of designs, whether you intend for them to lean towards the traditional or the contemporary style.

This capacity to create bespoke designs is what makes slate one of the best materials to work with and why one of our customers chose to use it in one of their latest projects in Central London, in which they undertook a complete bathroom and wetroom designed by an internationally renowned Japanese architect.

We used Elterdale Grey Green Honed Slate in a 400mm x 400mm format so that the tiles, both on the shower walls and the bathing area, had a smooth, matt surface with natural colour variations to them. For the base of the shower area, they used the same Elterdale Grey Green slate but in a Riven finish, which has a natural hand-split texture. This was to give a contrast to the different areas within the room but also to provide a safe, slip-resistant finish underfoot.

In order to meet the client’s very specific requirements and timescales we decided to take advantage of slate’s inherent properties, such as its durability and versatility, we ensured that the bathroom would be completely unique in appearance. We also hand-produced special rounded edge tiles for around the inset bath surround. Therefore ensuring a unique finished effect whilst providing clean and safe edges around the inset bath.

Slate can be tailored to fit your particular project. It also allows you to choose between an extensive range of styles, as well as shapes and forms, and be guaranteed a stunning and unique design. If you’d like to learn more about our bespoke slate ware and how it can benefit interior spaces such as a bathroom or a roof with our durable ridge tiles, or our Vermont slates, feel free to talk to us on 015395 59289. You can also speak to us to find out more about how our various slates could improve your existing premises.

Slate is an excellent material for your roof tiles. When maintained, it can not only protect your roof but look great at the same time.

So, Learning how to lay slate roof tiles is an important skill when repairing or replacing a slate roof; and, if done correctly, will save you time and money on your roof maintenance. Please read our following guide to learn everything you need to know about laying slate roof tiles. Laying a slate roof can seem like a daunting job, but with careful patience and suitable materials, it can be done efficiently and to a high standard. There are three main steps to follow:

When conducting any roof maintenance, you should always be aware of correct safety procedures. Performing home maintenance without regard for proper safety is a dangerous idea that could lead to personal injury or at least cause more damage to your home.

When working with Roof Slates, you should take time to put protections in place. Scaffolding is the best access method, but keeping the ladder fixed firmly to the side of the house will do if you’re only repairing a small section of your roof. An additional hook ladder would be helpful, but this will be explained later. Having a volunteer spot the bottom of the ladder while you work is essential.

Find some adequate clothing and footwear. Rubber-soled shoes and thick gloves are a good start. In addition, wearing a hard hat and a coat with thick sleeves will give you the best protection in case of any accidents. Purchasing some plastic goggles will also give you excellent eye protection when working with slate.

Slate tiles are incredibly durable but are dangerous to walk across. The slope angle on most roofs means you could easily slip and fall, so you should take care when walking across them. Older slate roofs can be particularly concerning as they may be more fragile.

Having a hook ladder comes in handy here—this type of ladder hooks over the Ridge tiles at the peak of the roof. The hook ladder allows you to distribute your weight between the ladder and the roof. It is essential that you gradually distribute your weight evenly when walking on a roof.

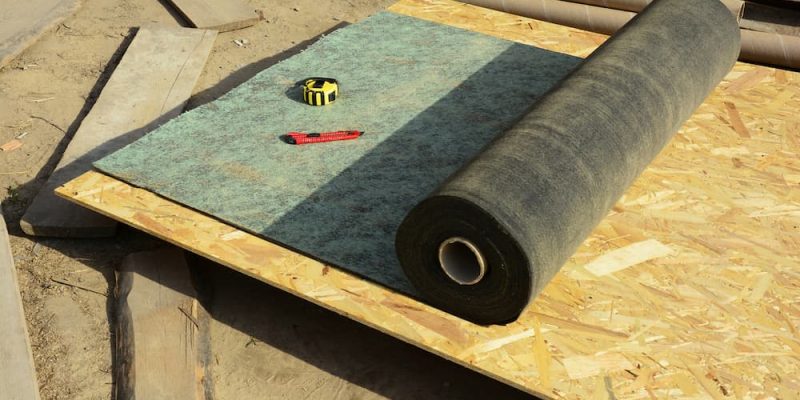

The roof underlay is sometimes referred to as membrane or underlayment. Regardless of the name, they all do the same thing. Essentially your underlay will keep any moisture from penetrating the tiles and entering your building.

You should check the rafters for any old nails or debris that could damage the underlay before your roll it out. Once you are satisfied, you can begin laying your underlay. Start from one side and move across the roof, ensuring it’s flush against the verge. Nailing the start of your roll down will help keep the underlay in place as you move across the roof.

You can nail the underlay again along the middle, but this isn’t strictly necessary. Instead, nail the underlay again once you’ve reached the other side of the roof to secure it in place.

Now you have your underlay in place; you need to place your first battens. You will also need one under eaves slate tile and two full-sized stale tiles to proceed.

Place the battens on the roof but don’t fix them down yet. Then place one of the full-sized slate tiles on the batten and allow a 50mm overhang. Finally, fix the tile to the batten using temporary fixings.

The second batten will go beneath the slate tile near the first batten. Next, place the eaves slate tile into the second batten whilst making sure the eaves slate reaches the bottom edge of the roof.

A third batten is fitted below the top of the slates. Take the other full-sized slate tile and place it centred on the top of the third batten.

By fitting these initial three, you can now calculate your batten gauge. Then, measuring from the top of one batten to the top of the one next, you can figure out where the rest of the battens should go.

To figure out how to set out your tiles correctly, we recommend drawing a chalk line from the ridge to the eaves at the width of every slate. Remember to allow a 5mm gap for the joint between each slate and the battens. This guide will ensure you don’t make incremental mistakes as you make your way across the roof.

It would be best if you lay your under eaves tiles first. Begin with a one-and-a-half slate to create a staggered pattern. Your first fill-length slate should be placed with its tail in line with the under eaves before nailing it in place.

Begin at the bottom and work upwards when placing your slates; bottom right to top left is recommended. This will help you avoid standing on slates as you place them and reduce any risk of slips or breaks.

Slate roofs are popular for many reasons, offering a classic aesthetic alongside an impressively durable lifespan. In addition, they can look vintage while being brand new, an excellent choice for buildings in cities or natural landscapes.

At UK Slate, we specialise in offering a fantastic range of natural slate roofing tiles. In addition, we can import North American, Spanish slates, Vermont slates and Welsh roofing slate and many more. So please get in touch with our expert team to discuss how we can help you with your roof slate needs today.

Slate is an aesthetically beautiful stone that has been used in construction for centuries. They make fantastic roof tiles, able to provide excellent insulation for a home and withstand harsh weather conditions, but they can also be used inside the house as floor and wall tiles. Slate comes in a variety of naturally occurring colours and styles, making it an incredibly versatile material.

But where do these slate tiles come from? How do they go from being mined out of the ground to the tiles on our roofs, wall and floors? Well, here’s what you need to know about the step-by-step process or mining this natural, raw material and turning it into the tiles we know and love.

Before the process can begin, quarry sites need to be surveyed and tested to ensure they are appropriate areas to extract the material from. The quarry rocks need to be tested to ensure they are strong enough and suitable for their end-use. The tests are done to discover if there are any weak rock layers that will be detrimental to the stone’s end quality.

The stone will only be extracted from the quarry for use when the tests have verified the quality and purity of the slate.

The raw slate is then sawn from the quarry in large flat slabs using a diamond beaded steel cable – or sometimes detonation is used, but this is done at a minimum to keep slabs large and prevent material loss. The extraction must be done carefully and with precision, as the process can affect the material’s integrity.

Once the slabs are free, they are transported to factories to transform them into tiles.

Using diamond-tipped blades, the slabs of slate are then cut into more manageable pieces. During this process, impurities are also removed from the raw material without the use of harsh chemicals. The cuts are then inspected for their end-use. Most slate will be used for roofing, while a portion will be allocated for architectural use. Slate destined for architectural use will need to be of the finest quality and have large dimensions.

The slate cuts are then sent for splitting, where they will be split down to a specific thickness, a process which is done by hand. This technical step of the slate processing process has been done for many centuries.

Splitting is a specialist process that splits the slabs into the correct thickness while maintaining the material’s integrity. The slabs are split where a natural break occurs in the slab to give it a clean, straight split.

Split slates are then ready to be trimmed to a specific length for its chosen purpose. Traditionally trimming was done by hand, but nowadays machines are used to trim the slate to perfect measurements for installation.

After the process is finished, the slate will go for a final inspection where the slabs will be sorted and classified for use. Slate for roofing will be stacked onto pallets for storage. Architectural slate for panelling, tiles, counter-tops and chalkboards etc., will go through various processes before it is completed. The slate will be gauged and then honed to various finishes and may even be flamed to give it an even textured finish that removes traces of the saw blade and any irregularities.

Once the slate has been completed and stored away, it can be delivered across the country and the world for its intended purposes. Here in the UK, we have a variety of slate quarries across the country, including in Wales and the Lake District.

Different parts of the globe provide different slate varieties, as the colour is determined naturally by the geological conditions at its formation, which varies from place to place. Wales is known for its stunningly beautiful variety of blue slates.

Here at UK Slate, we are specialist slate importers and exporters of natural slate from across the globe. We only source the very best globally and domestically thanks to our links to independent quarries, ensuring consistent and reliable supplies. We pride ourselves on our top-notch customer service and assure the very best support for you and your project.

You can browse our extensive range of slates on our website. Whether you’re looking or slate roof tiles, wall tiles or floor tiles, we will have something for you. Contact us today to find out more.